With the global rise of fitness trends, adjustable dumbbells have become a primary focus for major brands as essential equipment for home and commercial use. Many overseas brands collaborate through China-based OEM (Original Equipment Manufacturing) to produce and label products under their own brands. However, the OEM process involves multiple stages, including design, production, quality control, packaging, and transportation. Transforming a brand concept into a high-quality physical product requires a rigorous, structured workflow.

1. Requirement Confirmation and Supplier Selection

Problem: How can you ensure the selection of an appropriate supplier?

Conclusion: After clearly defining requirements, choose a supplier with quality certifications and extensive experience.

Requirement Confirmation:Brands should precisely confirm specifications, materials, and exterior designs for the adjustable dumbbells, as well as clear quality standards and certification requirements.

Supplier Screening:Select suppliers holding ISO 9001 and CE certifications to ensure production capacity and quality management standards. Priority should be given to factories with experience manufacturing for international brands, particularly those skilled in handling high-strength steel or aluminum alloys.

2. Product Design and Customization

Problem: How should product design and customization be handled?

Conclusion: Collaborate with suppliers through OEM to ensure the product design aligns with brand needs.

Design Collaboration: Brands can customize exterior aesthetics and functional adjustment mechanisms; if necessary, ODM (Original Design Manufacturing) services can be selected for full-service design-to-production.

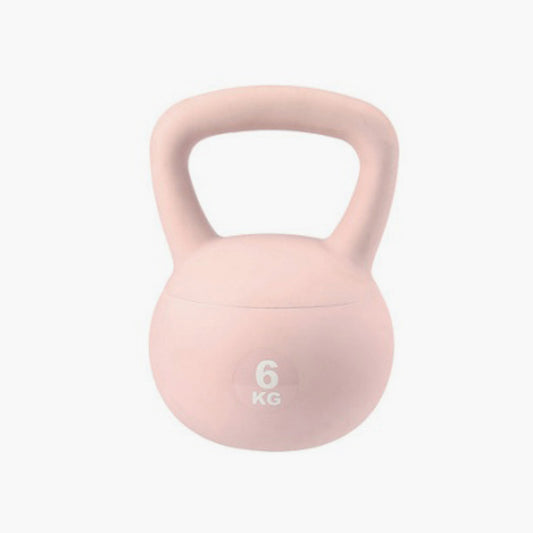

Customization Content: Adjustable dumbbell design includes colors, logos, weight plates, and grip designs. Packaging design is also critical for brand identification and should meet market aesthetics to enhance brand image.

3. Sample Confirmation and Production Preparation

Problem: How can you ensure samples meet expectations and production starts smoothly?

Conclusion: Ensure product quality through rigorous sample audits and production readiness.

Sample Confirmation: Once a supplier provides samples, the brand should comprehensively inspect appearance, quality, and functionality; third-party testing may be used to confirm compliance with international safety standards.

Production Readiness: After sample approval, the supplier begins preparation, including raw material procurement and production scheduling. The brand must work closely with the supplier to ensure the plan is implemented smoothly.

4. Mass Production and Quality Control

Problem:How can you ensure stable quality during mass production?

Conclusion:Guarantee batch consistency through strict production monitoring and quality inspections.

Production Monitoring:Brands can request phase-based reports from suppliers to ensure standards are met throughout the manufacturing process.

Quality Inspection:Suppliers must conduct quality checks during production and rigorous inspections before leaving the factory. Third-party inspection agencies can be introduced for final testing.

Certification and Testing: Ensure products comply with target market safety standards, such as CE, RoHS, or FDA certifications.

5. Packaging and Transportation

Problem: How can you ensure packaging and shipping meet brand requirements?

Conclusion:Customize packaging according to brand standards and choose suitable transportation methods for timely delivery.

Packaging Design:Packaging protects the product and promotes the brand. Ensure designs align with target market aesthetics, prevent transit damage, and effectively communicate brand information.

Logistics Choice:Select transportation based on the destination; sea freight is suitable for bulk goods but has longer cycles, while air freight is faster but more expensive.

Duties and Customs:Understand the tariff and clearance policies of the target market to ensure smooth entry and avoid unnecessary costs.

6. After-Sales Service and Customer Feedback

Problem: How can you ensure after-sales service handles quality issues promptly?

Conclusion:Ensure the supplier provides global after-sales support and establish an effective customer feedback mechanism.

After-Sales Guarantee:Require suppliers to provide warranty periods and repair services to ensure quality issues are addressed immediately.

Customer Feedback: Brands should establish feedback loops to continuously improve product quality and enhance brand competitiveness.

The China adjustable dumbbell OEM branding process spans requirement definition, supplier selection, design, quality control, packaging, logistics, and after-sales support. By precisely defining needs and maintaining close collaboration with suppliers, brands can maximize the cost advantages of Chinese manufacturing while securing a competitive edge in the global market through strict quality control and timely service.